Stop Condensation on Your Metal Roof: Everything You Need to Know to Keep It Dry

Condensation on metal roofs can lead to costly damage and reduce the lifespan of your roof if left unaddressed. This article covers what causes condensation, ways to prevent it, and solutions for moisture control, including insulation,

What Causes Condensation on Metal Roofs?

Condensation happens when warm air meets a colder surface, like a metal roof, creating droplets of water as the air cools to its dew point. Metal roofs are particularly susceptible because metal doesn’t absorb moisture. Factors that increase condensation include high indoor humidity, rapid temperature fluctuations, and lack of ventilation, which traps moisture in the attic or beneath the roof panels.

How Does Insulation Help Prevent Condensation?

Insulation is one of the most effective ways to prevent condensation on metal roofs. By stabilizing temperatures on the underside of the metal panels, insulation reduces the chances of reaching the dew point, which stops condensation from forming. For example, spray foam can seal gaps and insulate the roofing system, while rigid foam or fibreglass insulation keeps the attic space cooler in summer and warmer in winter. Insulating the roof creates a consistent temperature, which prevents condensation from developing on cold surfaces like metal.

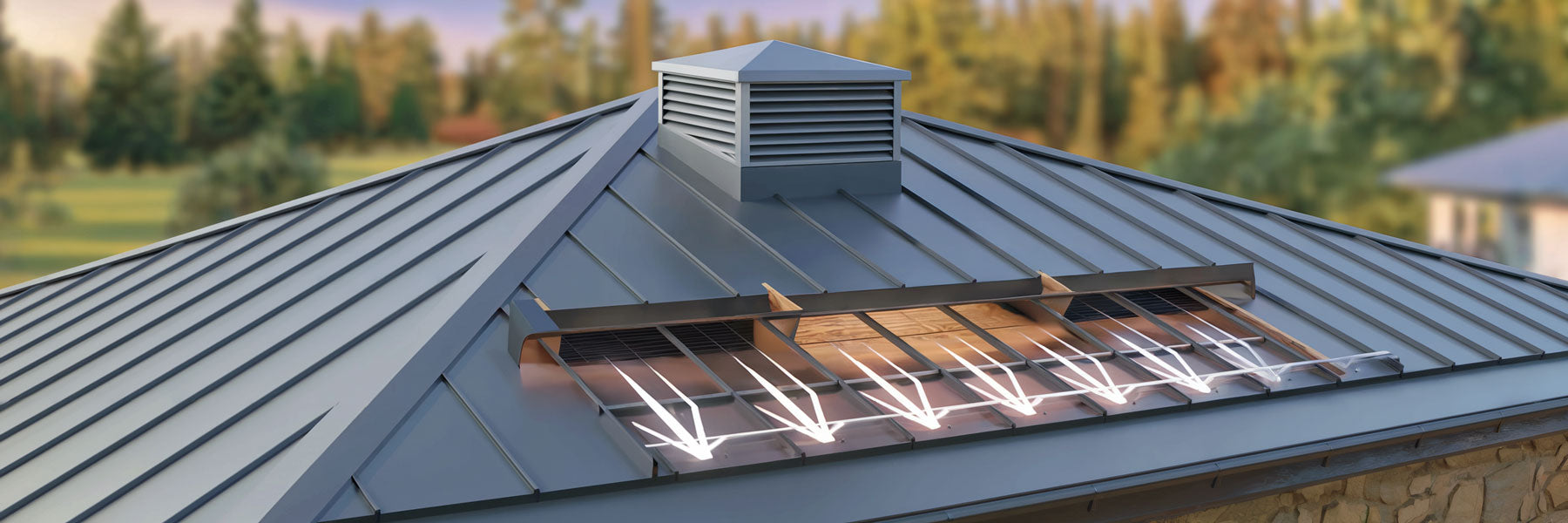

Why Ventilation is Key to Preventing Moisture Build-Up

Good ventilation allows moisture to evaporate and prevents excess buildup under the roof. Proper airflow, achieved through ridge and soffit vents, helps control humidity levels in the attic, reducing the risk of condensation. Ventilation minimizes warm air trapped near the metal roof’s underside and ensures that humid air escapes before it can cause condensation. Without proper ventilation, moisture buildup on the metal surface can lead to rust, corrosion, and other issues.

The Role of a Vapor Barrier in Metal Roof Construction

A

How to Identify Condensation Buildup on Metal Roofs

Condensation buildup on metal roofs may manifest as rust, water stains on insulation, or even visible droplets in the attic space. Over time, this moisture accumulation can cause peeling paint, mold growth, and corrosion on metal panels. Regular inspections, especially in high-humidity areas or after temperature shifts, can help identify early signs of condensation, allowing you to address the problem before it worsens.

Why Moisture Barriers are Essential Beneath Metal Roofing

Moisture barriers are critical in metal roof construction because they create a waterproof layer that prevents moisture from reaching the roof deck. Installed beneath the roof panels, moisture barriers help stop condensation by blocking humid air from directly contacting the metal panels. This layer of protection also allows moisture to evaporate instead of accumulating, keeping the roof structure dry and reducing the chances of corrosion and other condensation-related issues.

How to Prevent Condensation from Forming on the Underside of Metal Roofs

To prevent condensation from forming on the underside of metal roofs, you need to control both humidity and temperature. A way to prevent condensation is to ensure proper insulation and install a high-quality underlayment that regulates the temperature under the roof sheets. Some metal panels also benefit from specialized coatings that repel water, preventing droplets from forming. With an adequate roof pitch, excess moisture can also be directed away, reducing the risk of buildup beneath the metal.

Managing Excess Moisture in Your Attic Space

Indoor humidity can significantly increase condensation risks on metal roofs. Dehumidifiers, exhaust fans, and proper sealing of the attic space all help control moisture levels. Keeping the attic space well-ventilated and reducing the amount of warm air entering from the interior can prevent condensation issues. When humidity in the attic is controlled, it is easier to prevent condensation on metal surfaces and avoid issues such as rust and mold.

How Membranes Work to Control Condensation on Roofing Sheets

Membranes are installed beneath roofing sheets to act as an additional barrier against moisture. These specialized materials prevent humid air from reaching the metal surface, reducing condensation risks. Different types of membranes, from synthetic underlays to felt, can provide effective moisture resistance. When installed correctly, membranes work alongside insulation and ventilation systems to keep metal roofs dry and prevent condensation buildup.

The Importance of Routine Maintenance to Avoid Condensation Issues

Regular maintenance is essential to keeping a metal roof condensation-free. This includes checking for signs of moisture damage, verifying that insulation and ventilation are in good condition, and inspecting any vapour or moisture barriers installed beneath the metal roofing panels. Routine maintenance tasks, such as sealing gaps and removing debris, also ensure that the roof remains well-protected and capable of withstanding moisture buildup.

Summary of Key Takeaways

- Understand the Causes: Condensation forms when warm air meets a cool surface, such as a metal roof.

- Insulate the Roof: Proper insulation stabilizes the roof's temperature, preventing condensation.

- Ventilation is Essential: Ridge and soffit vents reduce moisture by allowing airflow beneath the roof.

-

Install a

Vapor Barrier :Moisture barriers prevent humid air from reaching the cold metal surface. - Identify Condensation Early: Look for signs like rust, mould, and water stains to catch issues early.

- Moisture Barriers are Important: A moisture barrier under the roofing system keeps moisture from accumulating.

- Control Attic Humidity: Use dehumidifiers and exhaust fans to manage indoor humidity.

- Choose the Right Membrane: Membranes add a moisture-resistant layer under metal roof sheets.

By implementing these measures, you can keep your metal roof free from condensation and maintain a safe, dry interior environment.