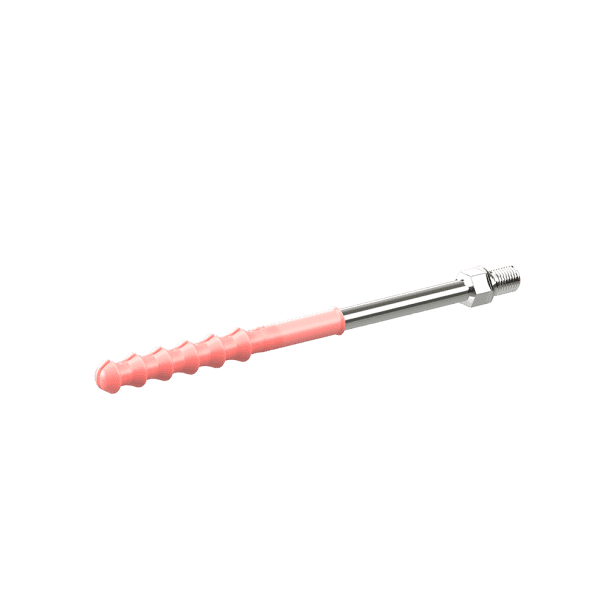

The wall plug for the steel clamp allows the entire downpipe system to be maintained in the desired position. Pipes fastened with its help are permanently attached to the building’s walls, ensuring that the steel pipe remains in place even under very unfavourable weather conditions during strong winds, heavy downpours, and significant overloading.

The wall plug is a long screw enclosed within an expansion anchor. When unscrewed, this anchor has only a slightly larger diameter than the screw, allowing it to be inserted into a pre-drilled hole. However, upon screwing in, the anchor expands laterally and locks into place. This method achieves an exceptionally durable bond between the metal wall plug and the concrete wall.

Such a method of securing steel downpipes guarantees their utmost durability and stability during harsh weather conditions. Consequently, it enables all rainwater to be diverted away from the roof area, thereby protecting the building’s facade and the surrounding grounds.

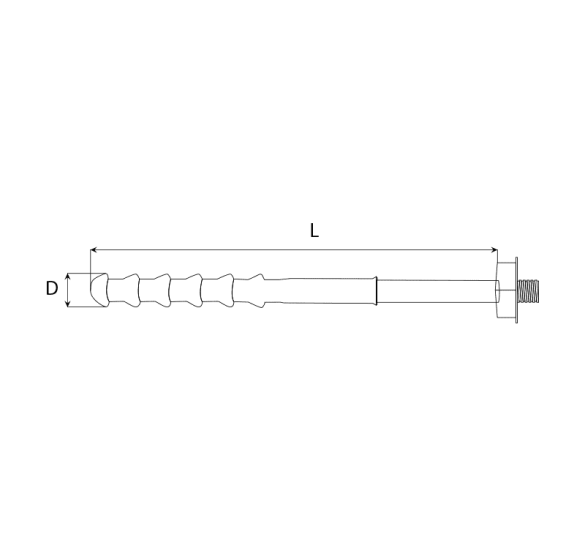

Technical Specs

| System | D | L |

|---|---|---|

| 63 | 12 mm | 100, 160, 200, 260, 300 mm |

| 90 | 12 mm | 100, 160, 200, 260, 300 mm |

Available Colours

| alucynk | black | terra cotta | blue grey | light brown | dark brown | red | chocolate |

|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  |  |

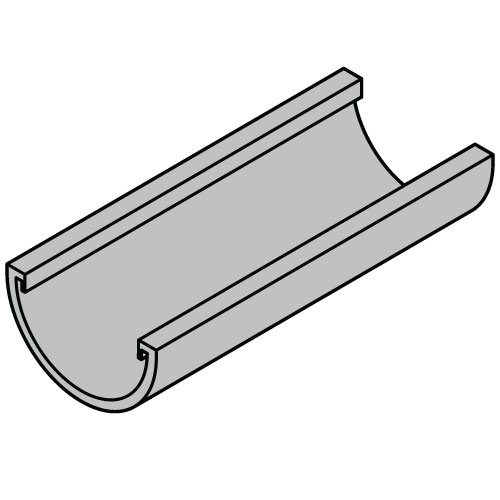

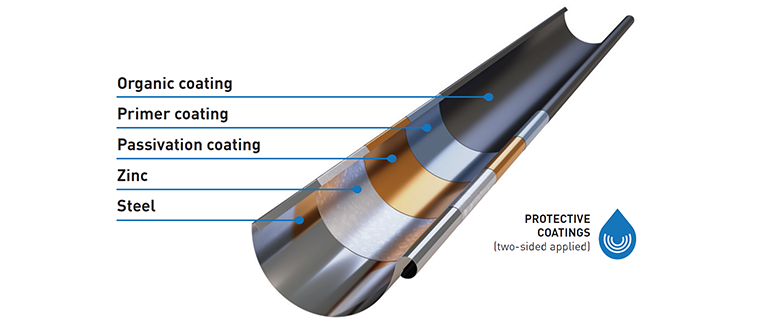

Steel gutter cross section

Our high-quality steel gutters are manufactured with four layers of protective coatings to ensure durability and performance. This superior construction includes a zinc layer applied directly to the steel for corrosion resistance. A passivation layer follows, promoting strong adhesion for the subsequent primer layer, which further enhances the anti-corrosive properties and provides a secure bond for the final layer. The organic coating tops off the system, offering ultimate resilience against adverse weather and mechanical damage while also providing the gutter with its aesthetic appeal. The comprehensive coating process is applied to both the interior and exterior surfaces of the gutter, ensuring thorough protection.