The steel gutter clamp is an indispensable component for the correct installation of a rainwater drainage system from the roof. The steel downpipe clamp enables the pipe to be fixed to the facade in a permanent and robust manner. This is precisely why the selection of clamps for pipes is so significant. If you are in search of such items, you can find them at our sales outlets. These are the highest quality products designed specifically for the downpipes offered by Highland Roofing.

If you are seeking steel pipe clamps that will allow you to efficiently and effectively install a water drainage system, our products will serve your needs excellently. These components are constructed from high-quality steel, which retains its characteristics irrespective of temperature fluctuations. Furthermore, they are resistant to damage and rust, ensuring they maintain their perfect condition and appearance for many years.

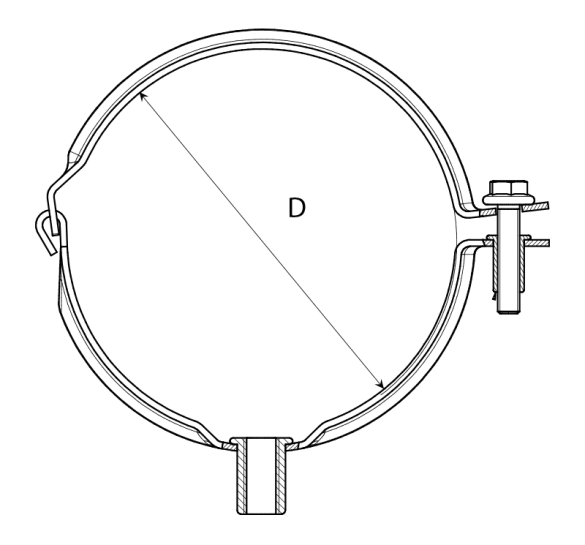

We offer steel pipe clamps in two size options (90 and 100) to accommodate different diameters, allowing you to select a model that fits the piping system of your building. It is essential that the steel pipe clamp is not only correctly sized but also properly mounted. Wall plugs, which are specialized screws for pipe clamps, are installed into the facade to support these elements. Downpipes are placed within the pipe clamps, which should be appropriately tightened at the end of installation because the clamp on the steel pipe must not be either too loose or too tightly fastened. It should ensure a stable attachment to the facade while also not damaging the pipe. Furthermore, downpipe clamps should be installed at suitable distances from one another, generally no less than 1.8 meters apart, to maintain the system’s integrity.

Technical Specs

| System | D |

|---|---|

| 90 | Ø 88.5 mm |

| 100 | Ø102 mm |

Available Colours

| alucynk | black | terra cotta | blue grey | light brown | dark brown | red | chocolate |

|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  |  |

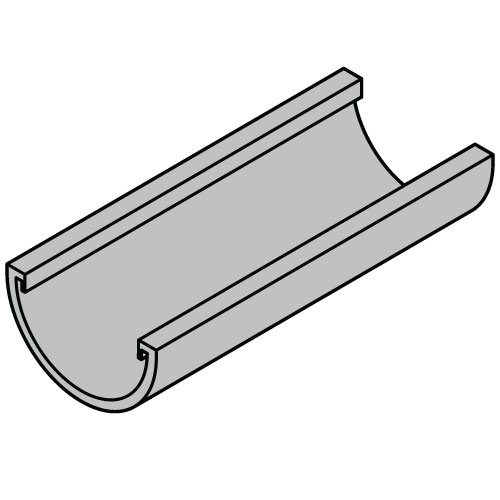

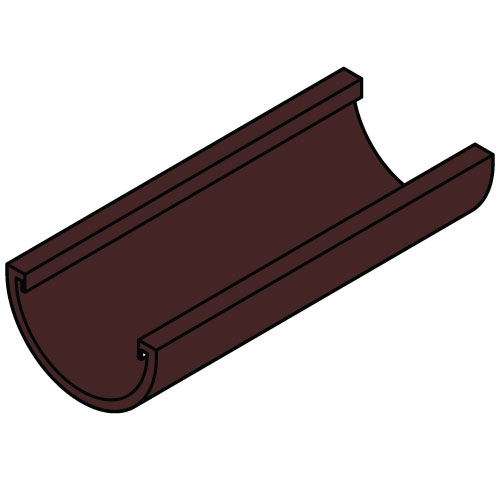

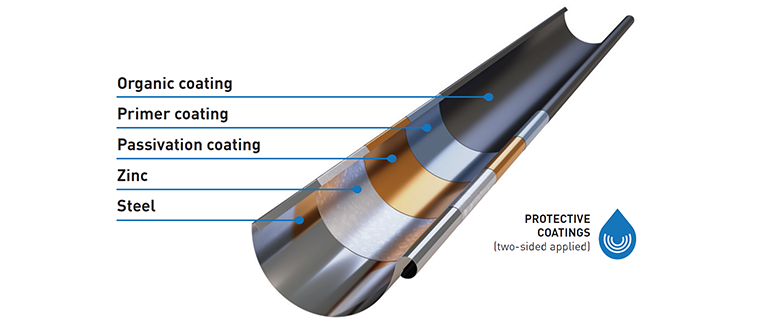

Steel gutter cross section

Our high-quality steel gutters are manufactured with four layers of protective coatings to ensure durability and performance. This superior construction includes a zinc layer applied directly to the steel for corrosion resistance. A passivation layer follows, promoting strong adhesion for the subsequent primer layer, which further enhances the anti-corrosive properties and provides a secure bond for the final layer. The organic coating tops off the system, offering ultimate resilience against adverse weather and mechanical damage while also providing the gutter with its aesthetic appeal. The comprehensive coating process is applied to both the interior and exterior surfaces of the gutter, ensuring thorough protection.